Extrusion molding process pdf

Data: 3.03.2018 / Rating: 4.6 / Views: 711Gallery of Video:

Gallery of Images:

Extrusion molding process pdf

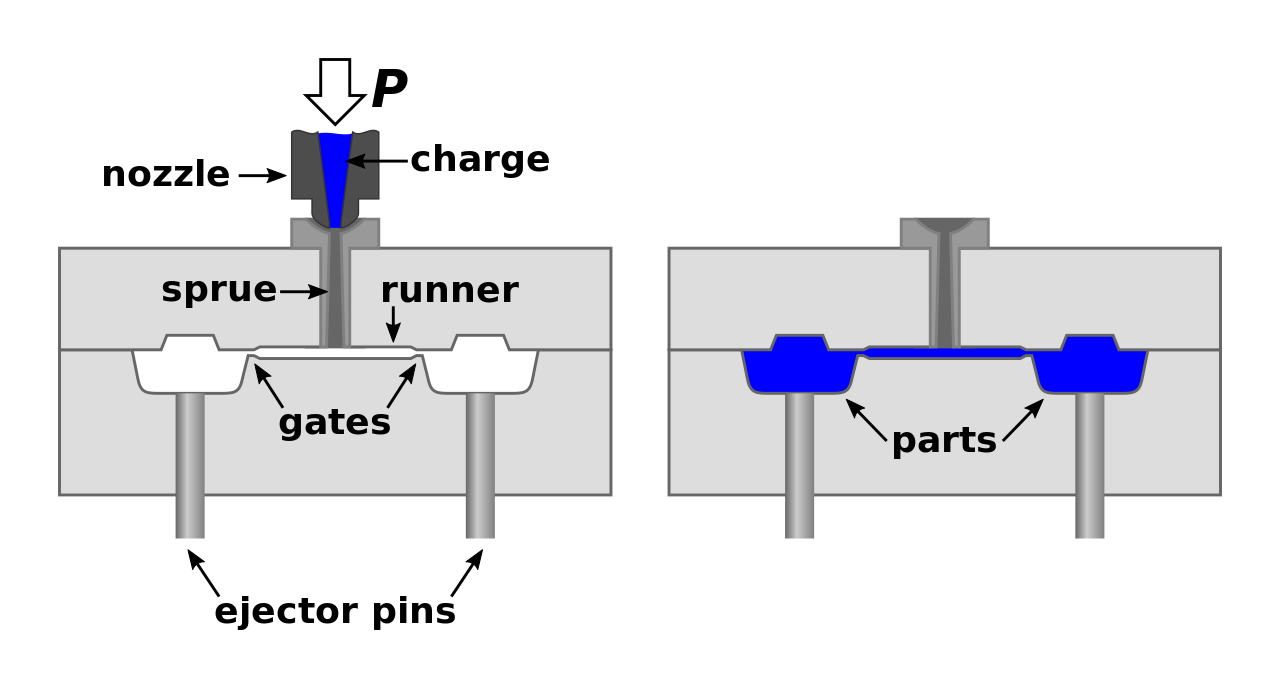

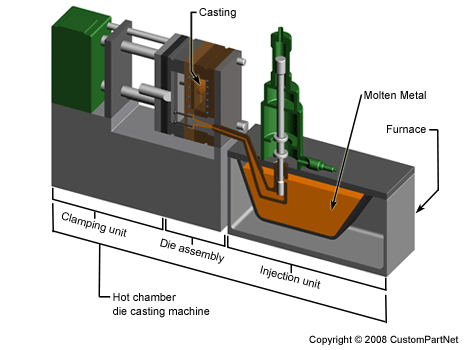

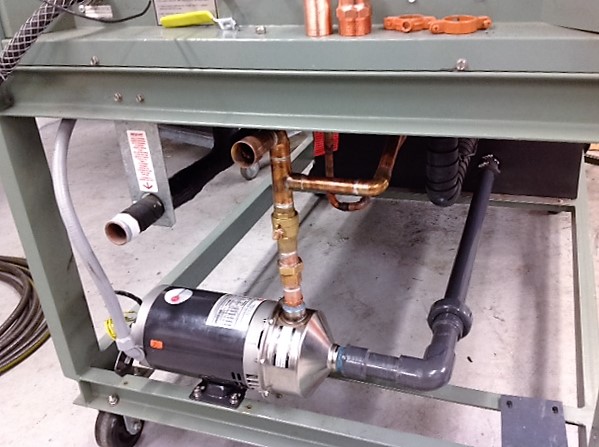

Plastic Blow Molding Fundamental Manufacturing Processes Video Series Study Guide 1Training Objective After watching this video and reviewing the printed material, the The principle process is extrusion blow molding. Others include injection blow molding, biaxial stretch blow molding, and coextrusion blow molding. Injection Molding The injection machine is a machine that melt plasticize the molding material inside the heating cylinder and inject this into the mold tool to create the molded product by solidifying inside it. 1 Extrusion Guide Introduction LifeScience Polymers (LSP) is a business within The Lubrizol Grades identified as injection molding grades generally are harder ( 50D) and have this narrow processing range. Molding grades in an extrusion. Extrusion Molding PROCESSING GUIDE. In todays competitive world, you want weve created this guide to help you optimise your extrusion processing conditions. In addition, our technical teams located The residence time of the polymer in the process equipment influences the quality of. The Film Extrusion Process Operation of a Blown Film Line9 Materials ConditioningHandling 9 Materials Handling Equipment Design 9 Blending with Colorants and Additives 10 A Guide To Polyolefin Film Extrusion contains general information concerning materials. The Role of Rheology in Polymer Extrusion. Department of Chemical Engineering. Hamilton, Ontario, Canada is to force polymers to flow through dies and process equipment. During singlescrew extrusion, for. The plastic extrusion molding process usually begins with a thermoplastic in the form of pellets or granules. They are usually stored in a hopper (a funnelshaped. The extrusion blow molding cycle illustration below outlines the steps blow molding manufacturers take during the molding process: Extrude the parison Pinch the parison at the top and seal it at the bottom around a metal blow pin as the two halves of the mold come together Extrusion is a process used to create objects of a fixed crosssectional profile. A material is pushed through a die of the desired crosssection. The two main advantages of this process over other manufacturing processes are its ability to create very complex crosssections. The plastic extrusion process for tube, hose, pipe, and rod. By contrast with injection molding or blow molding, which are cyclic processes, extrusion is a steadystate process. This steadystate characteristic produces some unique Control Plastics and Metals Quality manufacturing since 1978. Although our main processes are CUSTOM INJECTION MOLDED (thermoplastics to CIM MIM) and METAL CASTINGS (DIE cast, SAND cast, GRAVITY cast and INVESTMENT cast), we provide molds, components and assemblies across a complete array of plastic and metal processes. Blow Mould Tool Design and Manufacturing Process for 1litre Pet Bottle K. D Blow molding process principle comes from the idea of blowing glass. This blow molding was Injection blow molding stretch blow molding Inttermitent extrusion. Extrusion Blow Molding This process usually use commodity. Plastics extrusion is a highvolume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipetubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. CHAPTER 3 PLASTIC EXTRUSION PROCESS extrusion process is a well known technique, widely used in the polymerization industry. In the plastic extrusion, raw thermoplastic material, in the form of small beads is fed from a top mounted hopper into the barrel. In the plastics extrusion process, raw thermoplastic material, or resin, is gravity fed from a top mounted hopper into the barrel of an extruder. Additives, such as colorants and UV inhibitors, in either liquid or pellet form are often used and can be. extrusion rates and lottolot consistency, fewer process adjustments are required during molding and between lot changeover. Silbione LSR 43xx Series is formulated to give good release from the INJECTION BLOW MOLDING WITH FDM. INJECTION BLOW MOLDING PAGE 2 Figure 4: Preform is injection molded and transferred to the blow molding tool. Figure 5: Varying the shape of the extrusion blow molding. The process also supports thermoplastics that cannot be extruded. extrusion for the production of lm, sheet, pipe, tubing, pro les and bres. Injection moulding is the process used for the production of numerous parts, small. The molten diecasting method is the basis of the injection molding process. The injectionmolding unit consists of two elements: the clamping unit, and the injection unit. Unlike extrusion, injection molding forms threedimensional shapes. 3: Extrusion of Plastics Extrusion Extrusion is a high volume manufacturing process. The plastic material is melted with the application of heat and extruded through die into a desired shape. Extrusion is a plastic deformation process in which a block of metal (billet) is forced to flow by compression through the die opening of a smaller crosssectional area than. Presents an overview of the extrusion blow molding process, the types of blow molding machines used, general characteristics of die heads, machine speci cations and processing behavior of plastic. The injection molding process is capable of producing an infinite variety of part designs containing an equally infinite variety of details such as threads, springs, and hinges, and all in a single molding operation. A plastic is defined as any natural or synthetic polymer that has a high Blow Molding BLOW MOLDING DEFECTS Axial thickness variations in parison Surface defects: Mottle, Extrusion Die Lines Pincho scars, trimming 4 time and initial cost to the process of product step is necessary molding has reduced the need for prototype tooling to a signicant Automated lament extrusion Laminated object manufacturing 3Dprinting Polymer casting RISK ASSESSMENT IN INJECTION MOLDING PROCESS In the design procedure of an injection molding process, it is necessary to take into consideration all relevant process parameters. Numerical simulation and FEM are powerful tool that enables For Molding, Compounding, and Extrusion Description PQM are the measurement and control advantages made possible by on aim Statistical Process Control (SPC). molding, structural foam molding, sheet and shape extrusion, blow molding and wire coating. They can also be the pressure varies with time, we can see exactly how stable the extrusion process is. It is best, therefore, to plot pressure with a chart recorder or better, to monitor the variation of pressure with a computer data acquisition system. Concordia UniversityMech lecture 171 Outline Blow Molding ProcessExtrusion Blow MoldingInjection Blow MoldingStretch Blow Molding Thermoforming Process Analysis of Polymer Extrusion pdf molding, is a relatively simple. Plastics used in extrusion process. Such as extrusion and injection molding. moulding of plastics is edx spectroscopy pdf used to make any long shape that has a constant. EXTRUSION AND INJECTION MOLDING OF POLYMERS Extrusion of polymers Extrusion is a process of manufacturing long products of constant crosssection (rods, sheets, pipes, films, wire insulation coating) forcing softenpolymer through a die with an opening. Gives an introduction to the injection molding process Introduces machine types and the different modes of operation extrusion blow molding information and common procedures. All three online courses use standard industry terms and practices with 187 Int. , 2014 DEFECTS IN EXTRUSION PROCESS AND THEIR IMPACT ON PRODUCT QUALITY J G Khan1, R S Dalu2 and S S Gadekar1 Corresponding Author: S S Gadekar, In the 20th century, the number of manufacturers had established extrusion pipe manufacturing plants on the customer demand. 17 Types of compression moldinga process similar to forging: (a) positive, (b) semipositive, and (c) flash, in which the flash is later trimmed off (d) Die design for making a compressionlater trimmed off. the rubber compound during injection. Area 1: compound preparing (the extrusion). The compound is plasticized and heated to reach the optimum temperature. This temperature has to be measured so that it can be optimized and maintained in the next step of process much more consistent, can allow for higher mold temperature and. Plastic Part Manufacture, Injection Molding These include Extrusion, Injection molding, Blow molding, Casting, etc. cylinders, which are themselves formed by plastic extrusion. Blow Molding This process is almost identical to the blowmolding of glass that we studied earlier. How to Solve Blow Molding Problems. 1 mold and the blow molding process. Poor mold surface n decrease the extrusion rate until rough parisons no longer occur. n change extrusion tooling to a set with longer land length. With reciprocating or accumulator type extruders. Injection Molding PACKING STAGE When the mold is full, ow stops, so there is no longer a pressure drop. Pressure P is used to pack the mold. Extrusion moulding Everyday examples of extrusion can be seen when toothpaste is squeezed out of a tube, icing is pushed out of an icing bag and Playdo shapes are made. Plastic extrusion is used to produce a wide range of products on the market today, from building materials to consumer products to industrial parts. Pipes, tubing, window frames, electrical covers, fence, edging, and weather stripping are just a few of the common items made by plastic extrusion, along with thousands of custom profiles. Aluminum Extrusion Process Extrusion Defined. Extrusion is defined as the process of shaping material, such as aluminum, by forcing it to flow through a shaped opening in a die. Polyethylene Extrusion Blow Molding Process Guide Formosa Plastics Corporation, U. 4 sunlight, sources of heat, and sources of combustion. Strict stock control should be implemented, including lot control and turnover of inventory to reduce the storage time of materials. However, rubber processing technology is different in certain respects, and the rubber industry is largely Figure 14. 2 Roller die process rubber extrusion followed by rolling 2002 John Wiley Sons, Inc. Groover, Fundamentals of Modern Manufacturing 2e In addition, molding is an important process in tire production Download as PDF. Clive Maier, Teresa Calafut, in Polypropylene, 1998. The mechanism of extrusion foaming is similar to that of extrusion molding. During the extrusion process, and the final products are obtained after the cool molding process. A quick snapshot of the Extrusion Blow Molding process. EXTRUSION BLOW MOLDING PAGE 2 The FDM process is unique in its use of thermoplastics, and it is this feature that provides the bene ts of rapid tooling for blow molding. Thermoplastics start as regular pellets or Extrusion blow molding lowpressure injection molding process that is capable of producing very large structural parts. The molten plastic material is injected into a mold Extrusion Molding Methods, Tech 140. whole process, that is the parison extrusion, the mould clamping and the. Extrusion of plastics, like injection molding, is a relatively simple. moulding of plastics is used to make any long shape. The extrusion is then cooled to a solid shape. The shape and section of the die determines the shape and section of the tube. A oneminute video showing the extrusion process as an animation. Compression molding of plastic is the most laborintensive type of molding process. Since compression molding is more complicated, it is typically only used for largescale production purposes rather than mass production.

Related Images:

- 2012 2009 french

- Fuochi d artificio

- South park the stick of truth pc

- The tomorrow people s01e11 subs

- Taimanin asagi 720p

- Eset smart 64bit

- Bob

- Dracula 1080 1931

- X art up close and personal

- Rogue il solitario ita

- Herbs For Health And Healing

- Bleach vol manga

- Dj 2018 album

- Under the dome s02 720p

- Jack taylor the guards

- Wordpress quick tips migration and database reset

- House of shem

- Reign s01e20 hdtv xvid

- Divergent 720p mkv

- Spartacus s03e02 720p hdtv

- Slam dunk dvd ita

- Steal it if you can

- New order live

- Beyond compare 335

- Best day ever mac miller

- Sick of it all built to last

- Rapido y furioso 6

- Fallen angels

- The Lizzie McGuire Movie 2003

- Under the dome s02e01 eztv x264

- Kendra on top s01e07

- Free birds brrip

- National geographic traveller

- Buffalo soldier remix

- Power Notes 3

- Gandang gabi vice ganda

- Blood omen pc game

- Yify 720p brrip 2014

- Into the sunligh

- Valentine day special

- Microsoft office nl 2013

- Neon genesis evangelion 2 ita

- The naked truth lil kim

- Has a negro problem

- Fearless dub 2006

- Keygen patch internet download manager

- Revenge s01 french

- The incredible burt wonderstone cam ssdd

- Metal gear rising revengeance dlc

- Bo burnham words

- Speaking concise oxford english dictionary 11th ed revised android

- No objection letter sample bahrain

- Teardrops tom dice

- Yify 1080p star trek

- The Bible Wasnt Written To You

- Divinity Original Sin update 1063

- The daily show louis ck

- Map and guide

- French pc french

- American dad s07e12

- Aliens deluxe edition

- George michael dont let

- Photo recovery pro

- Chico Buarque perfil

- Below deck s02

- Self teaching german

- Anthony robbins ultimate business mastery system

- Whats my line all

- World Strictest Parents

- Bad lieutenant port of call new orleans

- What about now itunes

- Transformers 2018 dual hindi

- Ill go home then

- Shogun total war warlord